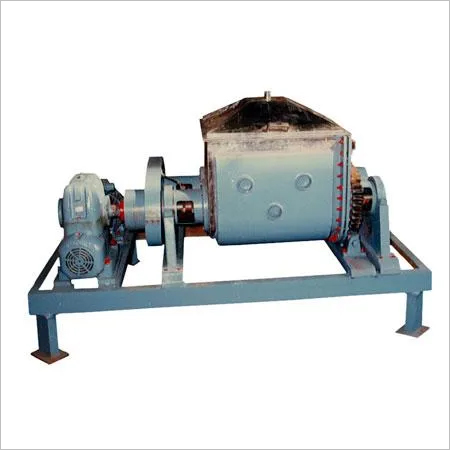

Manual Steam Jacketed Cookers

Manual Steam Jacketed Cookers Specification

- Speed Mode

- Fixed

- Operating Temperature

- Up to 180C

- Phase

- Single/Three Phase

- Feeding System

- Manual

- Noise Level

- Low

- Frequency

- 50-60 Hz

- Machine Type

- Jacketed Kettle

- Heating Method

- Steam

- Features

- Easy to clean, Energy Efficient, Corrosion Resistant

- Power Source

- Steam

- Automation Grade

- Manual

- Function Type

- Cooking, Mixing

- Product Type

- Steam Jacketed Cooker

- General Use

- Industrial Cooking, Food Processing

- Material

- Stainless Steel

- Type

- Manual Steam Cooker

- Capacity

- 50-200 Liters

- Weight (kg)

- 80-250

- Product Shape

- Round

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Installation Type

- Floor Mounted

- Voltage

- 220-240V

- Power

- 2-5 kW

- Dimension (L*W*H)

- Varies with capacity (Standard: 800 x 800 x 1200 mm)

- Raw Material

- Stainless Steel 304

- Feature

- High Efficiency, Rust Proof, Durable

- Color

- Silver

Manual Steam Jacketed Cookers Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 30 Days

About Manual Steam Jacketed Cookers

Offered Manual Steam Jacketed Cooker is made of 304 grade stainless steel. This cooking solution is used for preparing sauces, viscous syrup based substances and other processed dishes. This manually controlled equipment is appreciated for its uniform heating method, large cooking space, excellent thermal properties and simple installation process. Provided low cost non automatic system has been designed by skilled personnel. It comprises of necessary parts like pressure gauge for maintaining required internal temperature. Safety valve of this cooker is used for avoiding over temperature condition. Quality of this cooking apparatus has been verified on the basis of its service life, diameter, performance, output and operating cost. We would like to introduce ourselves as a growth oriented manufacturer and exporter of Manual Steam Jacketed Cooker.

Product Major Features:

- Anti Corrosive

- Best Market Prices

- Best Quality & Precise Size

- Design High Quality Standards

- Energy Savings

Durable, Hygienic Construction

Fabricated with food-grade Stainless Steel 304 and passivated surfaces, these steam jacketed cookers ensure hygiene and compliance with stringent ISO standards. The rust-proof body and robust design make them ideal for heavy-duty, high-frequency use in industrial kitchens.

Flexible & Efficient Operation

Experience reliable performance with manual control over steam pressure and cooking temperature, catering to a variety of food processing requirements. The cookers operate at up to 180C and are adaptable for industrial applications, ensuring energy-efficient and uniform cooking or mixing.

Enhanced Safety & User Convenience

Safety is prioritized with features like a pressure relief valve, ergonomic heat-resistant handles, and a sturdy, floor-standing design with adjustable legs. These cookers are easy to operate and clean, delivering consistent results while minimizing operational risks.

FAQs of Manual Steam Jacketed Cookers:

Q: How does the manual steam jacketed cooker operate and control temperature?

A: The cooker uses a steam jacket surrounding the inner vessel to evenly heat food. Its manual control system lets users adjust steam pressure (0.54 kg/cm), providing precise control over cooking temperatures up to 180C, allowing for flexibility during preparation.Q: What are the key advantages of using a steam jacketed cooker for industrial kitchens?

A: Benefits include energy-efficient heating, uniform cooking, and an easy-wash design. The rust-proof, food-grade stainless steel body ensures durability and hygiene, while adjustable legs, heavy-duty handles, and safety features make operation both safer and more comfortable.Q: When should I choose a fixed lid versus a hinged lid model?

A: A hinged lid offers easier access for continuous stirring or ingredient addition and is preferred when frequent opening is needed. Fixed lids are ideal for applications requiring secure, continuous cooking with minimal intervention, reducing the risk of spillage or contamination.Q: Where are manual steam jacketed cookers commonly used?

A: These cookers are widely utilized in hotels, restaurants, canteens, and food processing units across India and internationally, thanks to their large capacity, ease of cleaning, and compliance with food safety standards.Q: What cleaning process is recommended for this cooker?

A: Cleaning is straightforward due to the easy-wash design and smooth polished or matt finish. Users should allow the cooker to cool, open the drain valve for residue removal, and wipe all surfaces with food-grade detergents. The passivated stainless steel surface ensures quick and thorough cleaning.Q: How does the safety system in the cooker function?

A: The cooker is equipped with a built-in pressure relief valve, heat-resistant heavy-duty handles, and a robust mounting system. These elements collectively minimize risks associated with manual steam cooking by maintaining safe pressure levels and preventing accidental burns or movement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Frying Kettle

Price Range 300000.00 - 800000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Tilting Kettle

Machine Type : Fryer

Heating Method : Gas/Electric

Computerized : No

Kneader Mixer

Price Range 300000.00 - 800000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Other, Batch Type

Machine Type : Kneader Mixer

Heating Method : Electrical Heating/Jacketed

Computerized : No

Send Inquiry

Send Inquiry