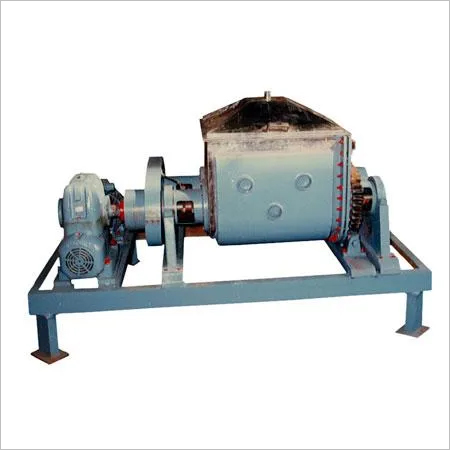

Kneader Mixer

Kneader Mixer Specification

- Speed Mode

- Dual Speed

- Function Type

- Mixing & Kneading

- Heating Method

- Electrical Heating/Jacketed

- Automation Grade

- Automatic

- Machine Type

- Kneader Mixer

- Noise Level

- Low

- Phase

- Three Phase

- Frequency

- 50 Hz

- Feeding System

- Manual/Auto

- Operating Temperature

- Up to 250C

- Power Source

- Electric

- Product Type

- Industrial Kneader Mixer

- General Use

- Mixing, Kneading

- Material

- Stainless Steel

- Type

- Batch Type

- Weight (kg)

- 1800 kg

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Floor Mounted

- Voltage

- 380 V

- Power

- 7.5 kW

- Dimension (L*W*H)

- 2200 mm x 1200 mm x 1700 mm

- Raw Material

- Stainless Steel

- Feature

- High Mixing Performance

- Color

- Silver Grey

Kneader Mixer Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 30 Days

About Kneader Mixer

With an aim to fulfill varied needs of different industrial applications, we are engaged in offering technologically advanced Kneader Mixer. The offered mixer is fully automatic (Tilting with Geared Motor) and is widely used for mixing, kneading and dispersing highly viscous material. The main Body with Blades can be offered in Stainless Steeel Grade AISI 304/316 as per clients requirement. Further, these Kneader Mixer is made available for clients in numerous specifications as per their needs and can be availed market leading rates.

Product Key Features:

- High performance

- Low power consumption

- Compact design

- Longer service life

Efficient and Durable Construction

Crafted from top-grade stainless steel, the Kneader Mixer ensures longevity and resistance to corrosion, making it suitable for continuous industrial use. Its rectangular shape maximizes mixing efficiency, reducing preparation time and ensuring consistent results even for demanding batches.

Advanced Automation for Precision

Equipped with a PLC control system and dual-speed mode, this mixer offers precise and adaptable operation. Automatic and manual feeding options enhance user flexibility. Its fully automatic process streamlines heavy-duty mixing and kneading, ideal for large-scale applications.

Versatility and Safety Features

Capable of handling a range of mixing and kneading functions, the Kneader Mixer operates efficiently within a safe, enclosed space. The electric heating or jacketed method ensures materials are processed at optimal temperatures, while the floor-mounted design ensures stability during strenuous operations.

FAQs of Kneader Mixer:

Q: How does the PLC control system benefit the kneader mixers operation?

A: The PLC control system offers precise parameter adjustment and automated control, enabling consistent high mixing performance and reducing the need for manual intervention. This ensures reproducible results and efficient operation during batch processing.Q: What types of materials can be processed in this batch-type kneader mixer?

A: This mixer is designed to handle a wide variety of ingredients, including dough, pastes, and other viscous materials commonly used in food, chemical, and pharmaceutical industries due to its high durability and stainless steel build.Q: When is the dual-speed mode most effectively used in mixing processes?

A: Dual-speed mode enhances flexibility: lower speeds are ideal for initial mixing, preventing splashing, while higher speeds are used for thorough kneading or intensive blending toward the end of the process.Q: Where should the kneader mixer be installed for optimal performance and safety?

A: The mixer must be floor-mounted in a level, well-ventilated industrial area with access to a 380 V three-phase power supply and suitable safety clearances for both the machine and operators.Q: What is the standard cleaning process for this stainless steel mixer?

A: After use, operators should disconnect the power, remove leftover materials, and wash the internal surfaces with approved cleaning agents. Stainless steel ensures easy cleaning and maintenance, supporting hygiene standards.Q: How does the electrical heating/jacketed method improve mixing operations?

A: Electrical or jacketed heating enables controlled temperature application up to 250C, essential for processes that require specific heat levels to achieve optimal mixing and kneading properties in various materials.Q: What are the main benefits of using this kneader mixer for industrial applications?

A: Key benefits include high mixing efficiency, robust construction, low noise level, automated process control, and energy-efficient operation, making it a reliable choice for continuous production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Manual Steam Jacketed Cookers

Price Range 300000.00 - 800000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial Cooking, Food Processing

Feeding System : Manual

Operating Temperature : Up to 180C

Power Source : Steam

Frying Kettle

Price Range 300000.00 - 800000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Commercial/Industrial Frying

Feeding System : Manual

Operating Temperature : Up to 300C

Power Source : Electric

Send Inquiry

Send Inquiry