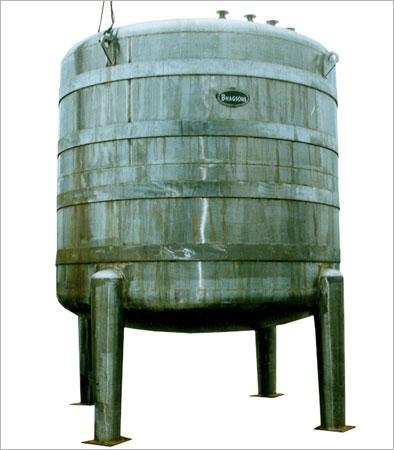

Blending Tank

MOQ : 1 Unit

Blending Tank Specification

- Material

- Stainless Steel

- Capacity

- 500 Liters

- Shape

- Cylindrical

- Application

- Beverage, Chemical, Food Processing Industries

- Power

- 3 kW

Blending Tank Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 30 Days

About Blending Tank

Blending Tank

With immense domain experience, we have emerged as one of the renowned manufacturers, exporters and suppliers of premium quality Blending Tank. It is globally used in the industries of chemical, pharmaceuticals, oil refineries etc for storing fluids and liquid. By following advanced engineering concepts, our technical experts manufacture this tank using premium quality raw material. Further, this Blending Tank is available in different sizes and capacities as per our clients specific requirements and can be availed at an economical price range.

Product Features

- Rugged design

- Anti-corrosive

- Durable finish standards

- Leak proof

Product Specifications:

- CAPACITY: 10 to 30000 liter

- CONSTRUCTION: Vertical cylindrical shell, ends dished or conical with/without legs

- MOC: Mild Steel/SS-304/316/316L

- AGITATOR: Turbine type with baffles/ propeller type

Versatile Industrial Blending Solution

The stainless steel blending tank is suitable for a wide variety of industrial sectors, including food processing, beverages, and chemicals. Its cylindrical shape ensures optimal mixing dynamics, while its generous 500-liter capacity can accommodate both small and large-scale production runs. The tank combines efficiency, durability, and hygienequalities essential for demanding production environments.

Energy-Efficient and Durable Design

Equipped with a powerful 3 kW motor, this blending tank delivers consistent results with low energy consumption. The use of high-grade stainless steel not only extends service life but also facilitates easy cleaning and maintenance, making it a practical choice for industries focused on productivity and operational safety.

FAQs of Blending Tank:

Q: How is the blending process performed in the 500-liter stainless steel tank?

A: The tank utilizes a 3 kW motor to power internal mixing mechanisms, ensuring thorough and uniform blending of ingredients. Its cylindrical design promotes efficient circulation, making it suitable for a variety of substances used in beverages, chemicals, and food products.Q: What industries can benefit from using this blending tank?

A: This tank is ideal for beverage, chemical, and food processing industries, offering reliable and sanitary mixing for liquids, viscous products, and powders, thanks to its robust stainless steel construction and efficient design.Q: When should a business consider upgrading to a 500-liter blending tank?

A: Businesses should consider this upgrade when their production volumes increase or when higher efficiency, hygiene standards, and consistent batch quality become essential for scaling operations in beverage, chemical, or food processing sectors.Q: Where is the blending tank manufactured and supplied from?

A: The blending tank is manufactured in India by an experienced exporter, manufacturer, and supplier with a solid reputation for serving both domestic and international markets.Q: What are the main advantages of using a stainless steel blending tank?

A: Stainless steel tanks offer excellent corrosion resistance, longevity, and ease of cleaning, providing both hygienic and low-maintenance operationespecially important in industries dealing with consumables and chemicals.Q: How does the tanks power rating affect operation?

A: With a 3 kW power rating, the tank ensures sufficient mixing force for a wide range of products, maximizing productivity while minimizing energy consumption and operational costs.Q: What is the typical usage process for this blending tank?

A: Users fill the tank with raw materials, activate the mixing mechanism, and monitor the process until desired homogeneity is achieved. After blending, the product is typically discharged through a sanitary outlet for further processing or packaging.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry